In the packaging industry there is increasing interest in producing germ-reduced or aseptic packaging material.

Accelerated electrons in voltage ranges of 80 - 250 keV with penetration depth in material of density 1 of 0 - 360 µm are particularly suitable for:

- surface sterilisation

- germ reduction in the depth of the packaging material

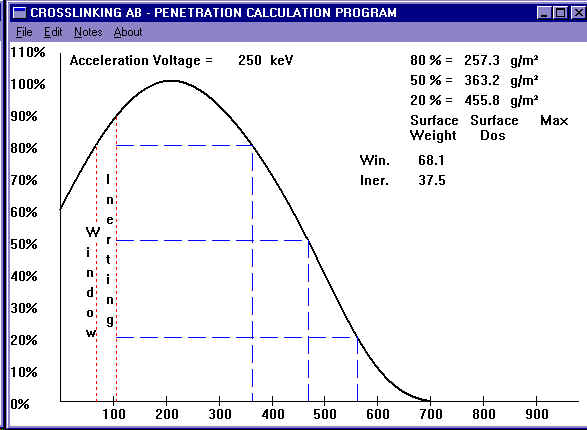

Accelerated electrons are calculable in their penetration depth. Fig 1 shoes the ionisation curve for 250 keV electrons. The ionisation density (number of events) is applied, standardised to 100 %, as function of the layer thickness. Parameter is the acceleration voltage.

Fig. 1 Depth dose distribution for 250 keV electrons after penetration of 15 mm Ti-foil and 30 mm air gap.

As with the surface sterilisation of packaging containers are the main concern low acceleration voltages are sufficient to reach the effect wanted.

Higher acceleration voltages become necessary when the containers to be treated have a larger expanse in beam direction and therefore the way of the accelerated electrons outside the electron-beam exit window becomes longer in order to envelope the container surface with electrons from outside.

When treating deep containers it must be considered that the dose within the container declines fast, as no scattered radiation can get into the inside of the container from the side.

Fig. 2 shows the electron cloud which makes the irradiation of three-dimensional parts possible,

Fig. 2 Excitation of electrons in gas, UB = 230 kV

Fig. 1 shows that also web-like materials can be made germ-free (within the layer) by using accelerated electrons up to layer thickness of 300 g/m2.

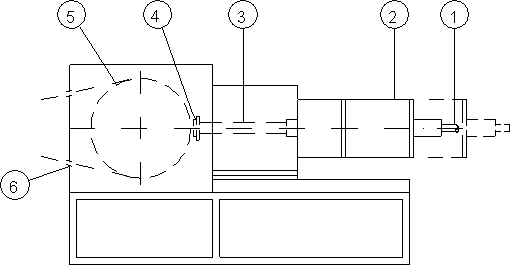

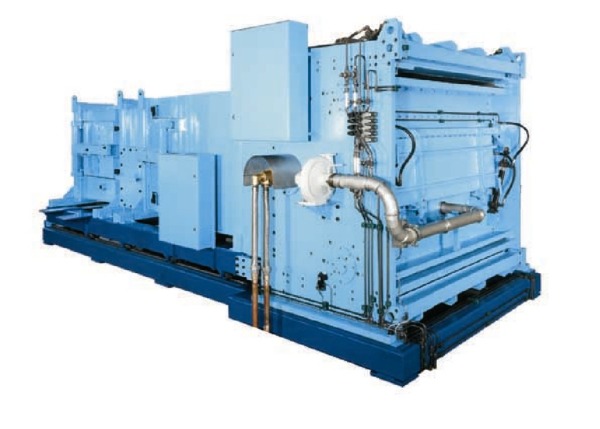

A suitable facility for this shows fig. 3 and fig. 4.

Fig. 3 EBC-irradiation unit for web-like materials (schematically)

- Accelerator

- High-voltage cable connection

- Scanning system

- Beam exit window, inertisation zone, disconnection point for maintenance work with locking system

- Drum with infeed unit

- Material inlet / outlet

An internationally established value for aseptic is 25 kGy (2,5 Mrad). This dose is certified to sterilize for a 7 log decrease in ISO standard 11137 and EU standard 552). When making trails it showed that by using low-energy electron beams the spore suspensions of the following micro-organisms were completely killed off:

- Bacillus subtilis

- Bacillus stearothermophilus

- Bacillus coagulans

- Bacillus globigii

- Clostridium sporogenes

- Penicillium chrysogeneum

- Aspergillus niger

These micro-organisms were place in dilutions of between 300 and 6 million per drop, i.e. 6000 to 120 million per ml.

Persuasive arguments helping our customer to make a decision of the crosslinking and vulcanising processes:

- No solvent emissions.

- Processing without sensitisers; and now also largely without monomers

- Minimal temperature increase through radiation process; therefore no migration of low-boiling components from the coating material; no change of moisture level in the substrate.

- High reproduction of the radiation process, even during raising and lowering of the plant; therefore minimal material losses.

- Precisely maintain crosslinking and vulcanising process conditions through very high dose precision over working width, depth of materials and production time.

- Substantial increase in production speed in comparison to heat treatment methods.

- The chemical reaction is completed immediately after the radiation process.

- Modest energy consumption.

- Modest space requirements.

Performance data of Electron Crosslinking AB Accelerators:

- Acceleration voltage 80 - 300 kV

- Electron current max. 200 mA/cathode

- Working width 0,2 - 2,5 m

- Electron flow per cm window length max: 3,2 mA/cm

- Speed of web at 10 kGy up to 800 m/min

- Distribution of dosage over working width better ± 5 %

- Productive penetration depth of electrons max. 390 g/m2 -incl. metals also-

- No cooling of electron exit window necessary

- The radiator may be installed in any position whatsoever

+46 (0)35 15 71 30

+46 (0)35 15 71 30