Ionising radiation with polymers may lead to a chain cracking and degradation of structure. On the other hand, however, ionising radiation generates crosslinking or vulcanisation, which then considerably improves the quality of the product.

When irradiating PSA the extension of the molecular weight and connected with this the material modification means:

- High cohesive and shearing strength within the adhesive layer as a factor of the dose

- Reduction of thermoplasticity and connected with this higher cohesive strength at increased temperatures.

- Improved chemical resistance.

- The crosslinked/vulcanised adhesives are resistant to chemical plasticizers as they, for instance, may emerge from PVC foils.

- Labels and masking tapes are removable from the ground or from the fresh lacquered surfaces without residues.

- Crosslinked adhesives may be formulated as permanent or as multi-removable adhesive-layers.

- Thick layers also may be irradiated at high speed as during the modification of the layers no components emerge.

- The irradiation with electrons result in a constant dosage within the adhesive layer between surface and carrier material. This is not guaranteed when using wave radiation (UV) only.

Irradiation with electrons hardly has any influence on

- tack

- peel strength

When applicating electron-beam radiation the addition of photoinitiators the adhesive is no longer necessary. This simplifies the formulation and makes the production of physiologically harmless adhesives easier.

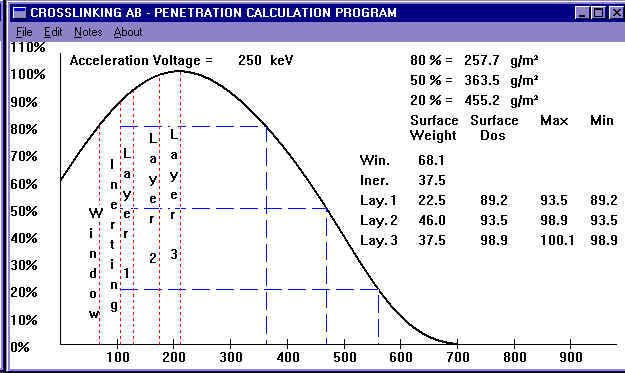

Electron radiation is calculable. As the cohesive strength of the adhesive layer is adjusted by means of the radiation dose, during irradiation high dose accuracy is necessary. Fig. 1 shows the depth dose distribution of ionization for 2 acceleration voltages as function of the layer thickness.

With a dose divergence of ± 10 % the penetration depth for 180 keV electrons is a layer thickness of 115 g/m2; the corresponding value for 250 keV electrons is 250 g/m2.

Fig.1 Depth dose distribution of accelerated electrons

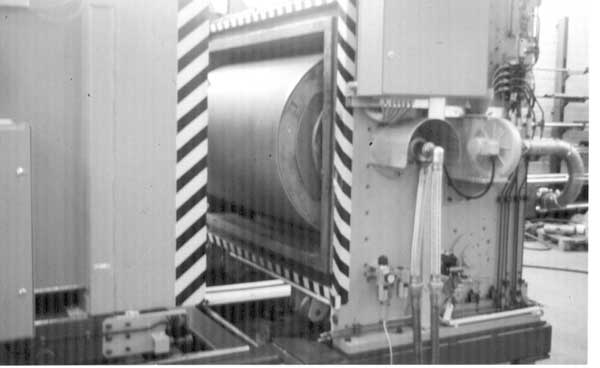

Fig. 2 shows a high-performance electron-beam accelerator in principle. The accelerator is positioned horizontally over the coated web. Irradiation is aimed towards a drum; the drum guides the material through the irradiation zone without strain.

Fig. 2 High-performance Electron-Beam accelerator (in principle)

- Accelerator with double cathode

- High-voltage cable connection

- Scanning system

- Vacuum pumps

- Electron-beam exit window, inrtization zone, disconnection point for maintenance work with locking system

- Drum for material supply

- Material inlet / outlet

- X-ray shielding

Fig. 3 EBC-unit for irradiation of materials from roll to roll

The industrial equipments for vulcanisation of PSA with accelerated electrons operate with web speeds of up to 160 m/min, with working width of 1300 mm.

The installations operate 24 hours per day. Flow rate up to 230.000 m2/day.

Applications of PSA crosslinked by EBC:

- Industrial double adhesive tapes

- Masking tapes

- Electronic industry

- Label industry, here particularly for critical applications at increased temperatures and nearby cleaning agents, lubricants and solvents.

- Motorcar industry

- Auxiliary for the erection of interior decoration

- Sticking of damping plates

- Production of cable forms

- Substitute for acrylate adhesives based on solvents

- Wherever conventional hot-melt PSA cannot be used due to their extremely high thermoplasticity as particularly adhesives with very good cohesive characteristics at room temperatures fail at temperatures higher than 60 ºC.

Persuasive arguments helping our customer to make a decision of the crosslinking and vulcanising processes:

- No solvent emissions

- Processing without sensitises; and now also largely without monomers.

- Minimal temperature increase through radiation process; therefore no migration of low-boiling components from the coating material; no change of moisture level in the substrate.

- High reproduction of the radiation process, even during raising and lowering of the plant; therefore minimal material losses.

- Precisely maintain crosslinking and vulcanising process conditions through very high dose precision over working width, depth of materials and production time.

- Substantial increase in production speed in comparison to heat treatment methods.

- The chemical reaction is completed immediately after the radiation process.

- Modest energy consumption

- Modest space requirements

Performance for Electron Crosslinking AB Accelerators

- Acceleration voltage 80 - 300 kV

- Electron flow per cathode max. 200 mA

- Working width 200 - 2000 mm

- Electron flow per cm window length max: 3,2 mA/cm

- Speed of web at 10 kGy up to 800 m/min

- Distribution of dosage over working width better ± 5 %

- Productive penetration depth of electrons max. 390 g/m2 -incl. metals also-

- No cooling of electron exit window necessary.

- The radiator may be installed in any position whatsoever.

- No measurable X-radiation outside protective screen.

+46 (0)35 15 71 30

+46 (0)35 15 71 30