Considering that some years ago solvent free systems savings in energy or low space requirements were the main arguments in favour of irradiation of surfaces to dry lacquer with low-energy electrons come to the fore:

- High scuff resistant coatings

- Controlled, calculable, through-curing

- Immediate stacking or subsequent treatment of the materials

- High flow rate, substantial increase in production speed in comparison to heat treatment methods

- Constant product quality, precise maintain crosslinking and vulcanising process conditions through very high dose precision over working width, depth of material and production time

- Considerably lower extraction values compared to UV-curing, processing without photoinitiators

- Acceptable costs at appropriate quantities

- Minimal temperature increase through radiation process; therefore no migration of low boiling components from the coating material. No change of moisture level in the substrate.

Today electron-beam curing (non-thermal curing) in used industrially for the surface technology in the following fields:

- Curing of pigmented lacquers on doors

- All-around curing of lacquers on mouldings

- Controlled through-curing of coatings on finished parquet

- High scuff-resistant floor-coverings

- Production of high-gloss surface in the board industry

- Curing of coatings on furniture foils (lacquer from the roll)

- Crosslinking of Lacquer on top of papers for the production of HPL (high-pressure Laminate) - and CPL (Continuos-Pressure Laminate)-material with lacquered surface

- Curing of coating on boards with UV-/EB-curing processes

- Even Crosslinking of pressure-sensitive adhesive masses (Tesakrepp-material) to increase temperature stability

- Drying of printing inks

Controlled, calculable through curing

Electron-beam irradiation is calculable and is determined by 3 factors:

Acceleration voltage as the measure for the penetration depth of the electrons.

Electron current

It determines the possible flow rate. The applied irradiation dose D is connected with the electron current I and the web speed v as follows with k as equipment factor.

with k as equipment factor.

with k as equipment factor.

The formula above shows the following details:

- Dose and electron current are directly proportional.

- If the proportion of electron current and speed is constant, you will receive reproducible and saleable products in all production phases including when starting up and shutting down the plant.

- The accelerator only takes power of the main supply according to the web speed.

- Quality protection is possible when using this formula.

Working width

The width of the electron-bean exit window has to be adjusted to the max. working width (object width).

Electron Crosslinking AB electron-beam accelerators

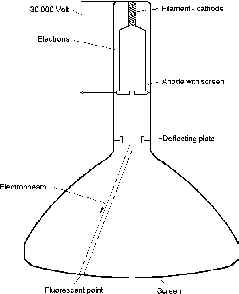

The function of our electron-beam accelerators can be compares to a cathode ray tube of a TV-set.

By means of flow of electron current a heated tungsten cathode puts free electrons at its surface to disposal in high vacuum. These negative charged particles (or waves) are accelerated by a negative voltage in direction to the anode and then deflected over the screen at cathode ray tubes or the electron-beam exit window at electron-beam accelerators. With the accelerator these electrons can pass though a thin titanium foil from vacuum out into the air or inertgas, where they can act on the object.

Performance for Electron Crosslinking AB Accelerators

- Acceleration voltage 80 - 300 kV

- Electron flow per cathode max. 200 mA

- Working width 200 - 2000 mm

- Electron flow per cm window length max: 3,2 mA/cm

- Speed of web at 10 kGy up to 800 m/min

- Distribution of dosage over working width better ± 5 %

- Productive penetration depth of electrons max. 390 g/m2 -incl. metals also-

- No cooling of electron exit window necessary.

- The radiator may be installed in any position whatsoever.

- No measurable X-radiation outside protective screen.

+46 (0)35 15 71 30

+46 (0)35 15 71 30